What is a BioBarrier Membrane Reactor? (MBR)

These are advanced systems designed specifically to treat all the wastewater (blackwater & greywater) generated onsite from single-family homes or other small-flow applications that far exceed effluent requirements. NSF/ANSI Standard 350 certified for Water Reuse (the first to receive this distinction), this provides new construction and renovation/repair projects in “water constrained areas” with new opportunities for water recycling. Another big benefit for the homeowners is having the use of their backyards. Now you have room for decks, patios, pools, outbuildings etc etc. The MBR unit significantly reduces the size of the absorption fields required. The MBR systems have turned unbuildable lots into buildable lots, whether it was an issue with the soils that would not allow a conventional wastewater treatment system or the topography.

Please do not confuse the MBR as a conventional septic or an Aerobic unit system, it is not. This is a true water recycling system and therefore cannot be treated as a conventional system. Since the elimination of phosphates in the everyday cleaning products we have found that Quaternary Ammonium products have an adverse affect on the biomass growth. You have to be conscious of what you are using in the household to protect the biomass development. If it gets killed off the MBR will do what it was designed to do and shut the pump off so you cannot send any contaminated or untreated water out to the absorption field.

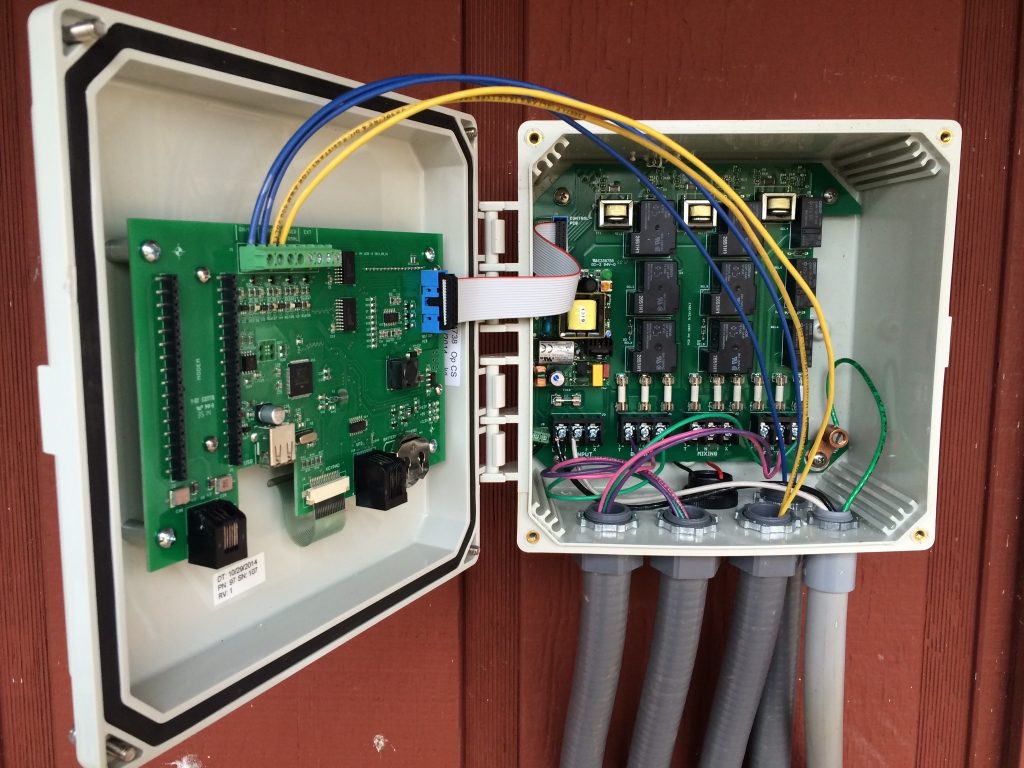

The BioBarrier systems allows Zeiter’s Septics to meet all of the challenging situations that we are faced with on a daily basis. We are proud of our team and we have the knowledge and experience to work through any and all situations that present themselves. Please review the pictures at the bottom of this page.

How does the System Work?

- The primary tank (we use a two-compartment monolithically poured) settling tank has a 4″ SaniTee filtering device to prevent large solids from entering the treatment zone where the 2nd compartment of the tank houses the MBR module.

- A blower with a 2″ airline blows air (oxygen) into the MBR module to facilitate a robust circulation of the wastewater.

- Inside the treatment tank, suspended treatment occurs. The Biobarier module and air grid create an upward flow between the membrane plates providing scouring action to reduce the clogging.

- The membrane pore size is specifically designed to allow for microfiltration and ultrafiltration.

- The clear, odorless treated water is ready for re-use applications or in most cases here in Illinois to be dispersed into very small absorption fields.

Why choose an MBR system?

If you want to have full use of your lot and not have the entire backyard used for the septic system.

If you want to recycle the water, you can reduce the amount of water use by over 40% or reuse the water for decorative ponds etc. etc. The NSF 350 certification means it is safe for human contact. Yes, I have washed my hands with the treated discharged water.

For septic repairs and or small lot size are candidates for the MBR.

If you are required to surface discharge and have to have an NPDES permit. This is the only system we will install to meet these requirements. We have five units with NPDES and they pass each and every sample.

Multi-Family & Community Systems HSMBR (High Strength Membrane Bioreactor)

Exceeding typical treatment effluent requirements of the local regulators, the multi-family FAST systems allow us to provide small communities, subdivisions, apartment dwellings, and other residential developments with highly treated effluent for us to provide opportunities for total wastewater recycling. An increase in property value is guaranteed with less aesthetic disturbance of property value due to above ground system components.